In 1974, 3m patented pavement marking tapes. Tapes we now know as Stamark pavement marking rolls. These tapes were meant to provide quick temporary striping for roads and are still widely used in construction zones. An issue that arose with this particular product was clean removability. When peeled from a roadway, temporary pavement marking tapes often fell apart or came off in pieces. So there was no easy way to remove them when a job was done and paint or thermoplastic was ready to be applied.

In 1974, 3m patented pavement marking tapes. Tapes we now know as Stamark pavement marking rolls. These tapes were meant to provide quick temporary striping for roads and are still widely used in construction zones. An issue that arose with this particular product was clean removability. When peeled from a roadway, temporary pavement marking tapes often fell apart or came off in pieces. So there was no easy way to remove them when a job was done and paint or thermoplastic was ready to be applied.

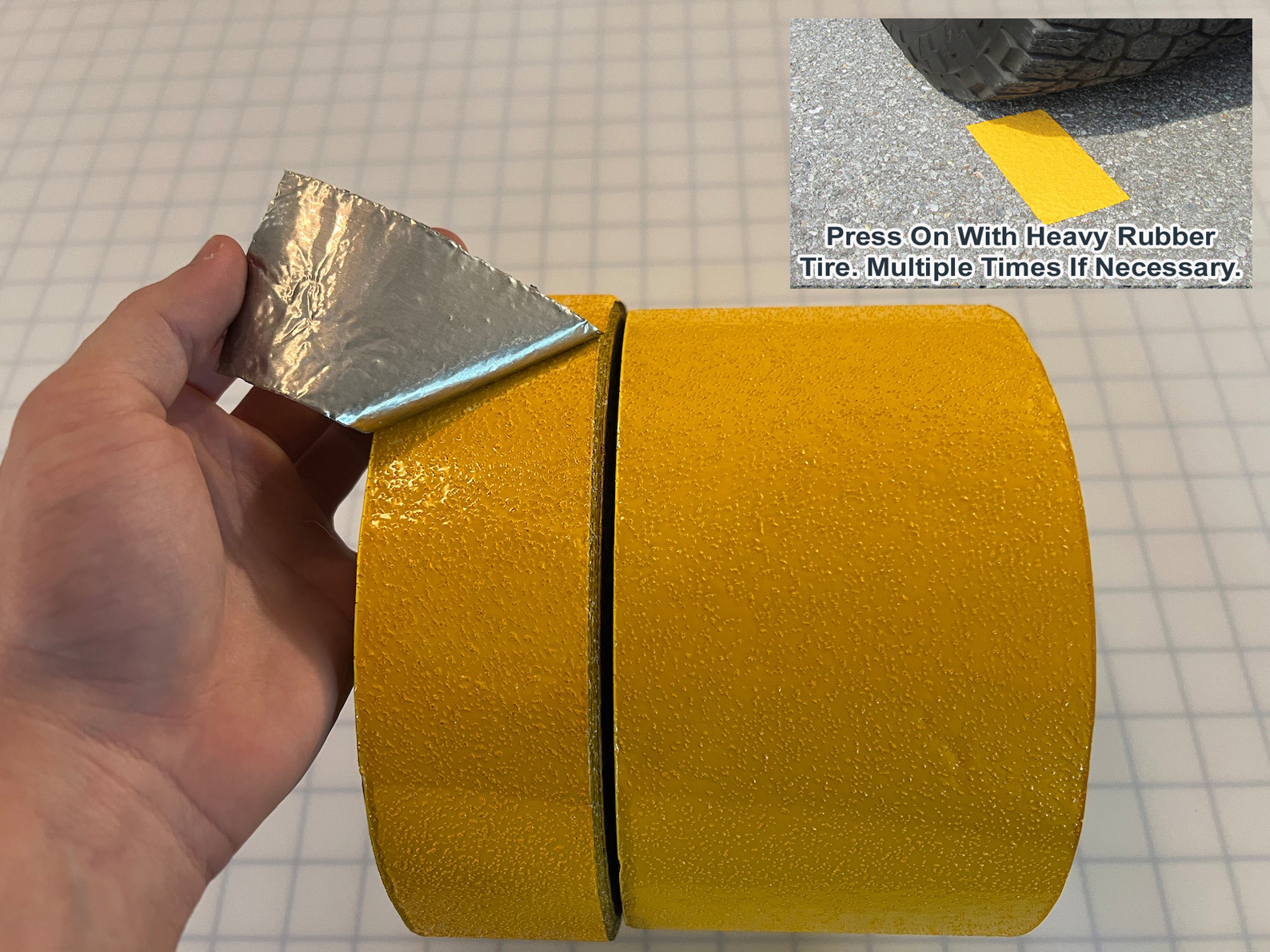

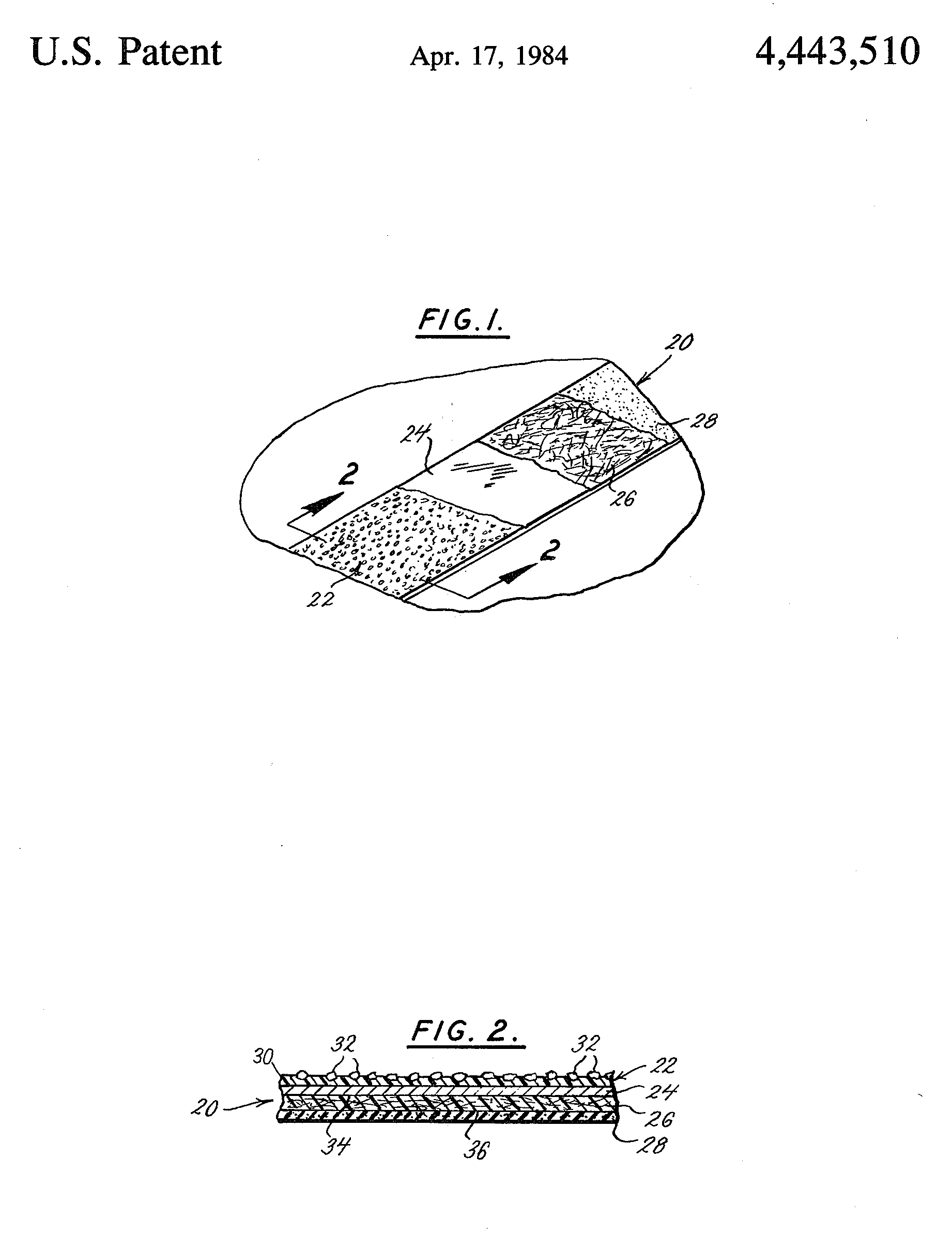

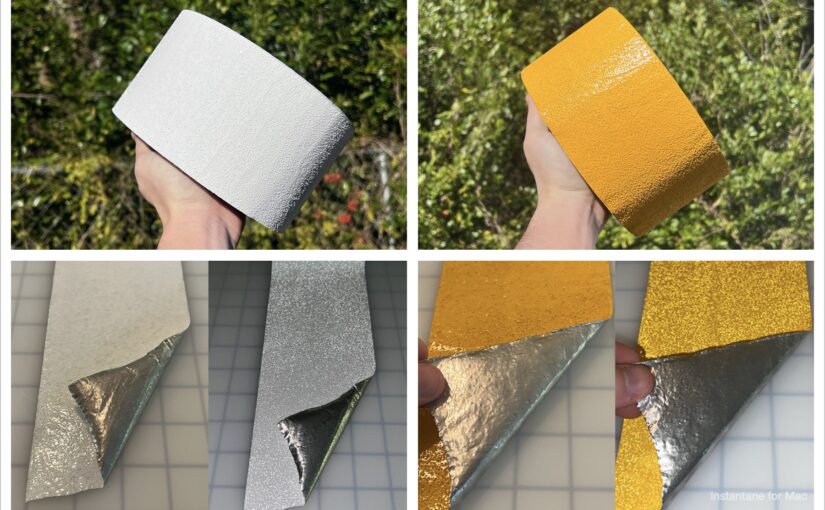

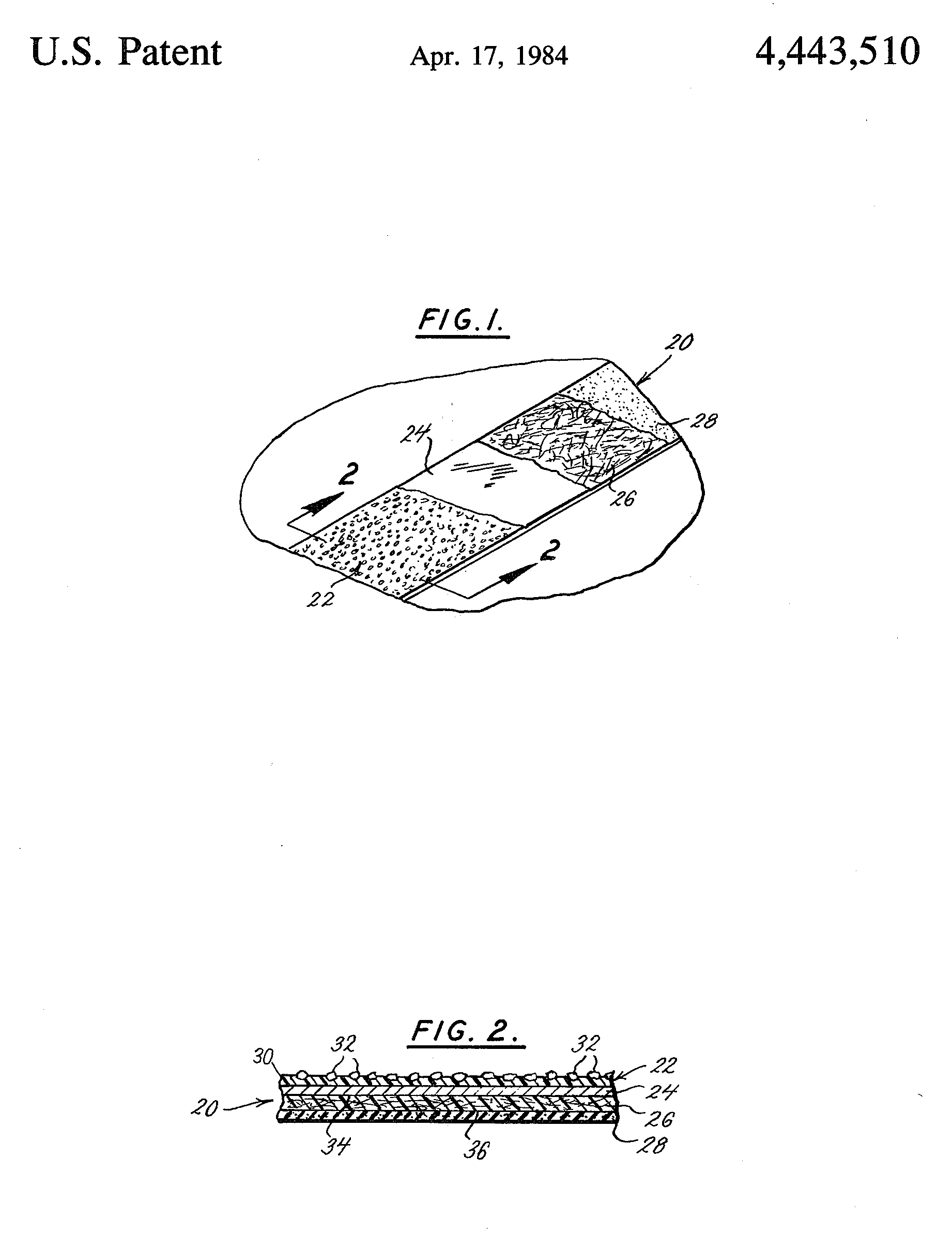

In 1982 Lukens General Industries Inc filed to patent an invention that would allow for more cleanly removable temporary pavement striping. In 1984 the patent was granted. This product would differ from 3m’s pavement tape in that its main component was aluminum sheeting or foil film. As you can see from the patent filing information below, this new tape consisted of an aluminum sheet, coated with paint and glass beads, layered with a polymer scrim, and then coated with an adhesive. So the layers are as follows from the top down – reflective glass beads, paint, aluminum, polymer scrim, and adhesive. The aluminum and polymer scrim helped the tape hold together during removal, which was one of the main goals of the invention. Also, the aluminum construction allowed the tape to mold or conform to the surface leaving very little edge, much like a coat of paint. From experience using this product, removal is as simple as peeling an edge and pulling it up. Or a torch can be used to flash the tape and cause it to release. The aluminum construction allows heat to quickly pass into the adhesive layer and vaporize it, thus releasing the tape.

In 1982 Lukens General Industries Inc filed to patent an invention that would allow for more cleanly removable temporary pavement striping. In 1984 the patent was granted. This product would differ from 3m’s pavement tape in that its main component was aluminum sheeting or foil film. As you can see from the patent filing information below, this new tape consisted of an aluminum sheet, coated with paint and glass beads, layered with a polymer scrim, and then coated with an adhesive. So the layers are as follows from the top down – reflective glass beads, paint, aluminum, polymer scrim, and adhesive. The aluminum and polymer scrim helped the tape hold together during removal, which was one of the main goals of the invention. Also, the aluminum construction allowed the tape to mold or conform to the surface leaving very little edge, much like a coat of paint. From experience using this product, removal is as simple as peeling an edge and pulling it up. Or a torch can be used to flash the tape and cause it to release. The aluminum construction allows heat to quickly pass into the adhesive layer and vaporize it, thus releasing the tape.

Here is a excerpt from the patent filing that goes over what the invention is –

From Patent – A multilayer reflective tape for use on roadways to provide temporary marking and demarcation of traffic lanes is disclosed. The tape has a thin malleable strip of aluminum, the top of which is coated with a high visibility paint in which reflective glass beads are embedded. Bonded to the bottom of the aluminum strip is a nylon felt scrim, the bottom of which is provided with a pressure-sensitive adhesive.

BACKGROUND OF THE INVENTION

From Patent – This invention relates to marking tapes for use on roadways to provide temporary marking and demarcation of traffic lanes. More specifically, this invention relates to removable marking tapes of high visibility and reflectivity having a long service life.

Temporary roadway marking tapes are known in the prior art, but have presented several problems. The most apparent and serious problem has been the difficulty of providing a tape that can withstand the substantial shear stresses applied by vehicle wheels. These stresses often cause the tapes to slide on the roadway, thereby detaching the tape. These stresses can also cause tearing, ripping and wrinkling of the tape.

A related problem is that a tape of sufficient adhesion to resist dislocation and damage is extremely difficult to remove when the location of the marker is to be changed. Prior tapes often tended to come off in bits and pieces instead of in the long strips in which they were applied. This was especially true of the metal-based tapes in the prior art, which although more resistant to wear, were nearly impossible to remove.

Yet another problem is that to resist the tearing and ripping caused by the stresses applied, the tape had to be thick. This thickness caused the tape to protrude from the roadway, subjecting it to even greater stresses as well as increased abrasion. The thickness also added to the weight and bulk of the tape, causing inconvenience in the shipping, storing, and handling of the tape.

SUMMARY OF THE INVENTION – from patent text

It is therefore an object of this invention to provide a removable, reflective marking tape that solves these problems.

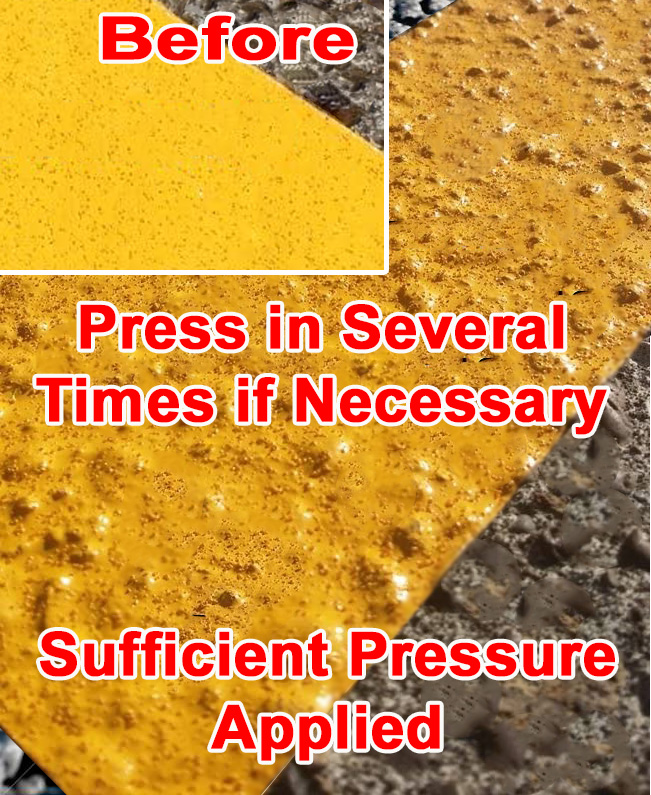

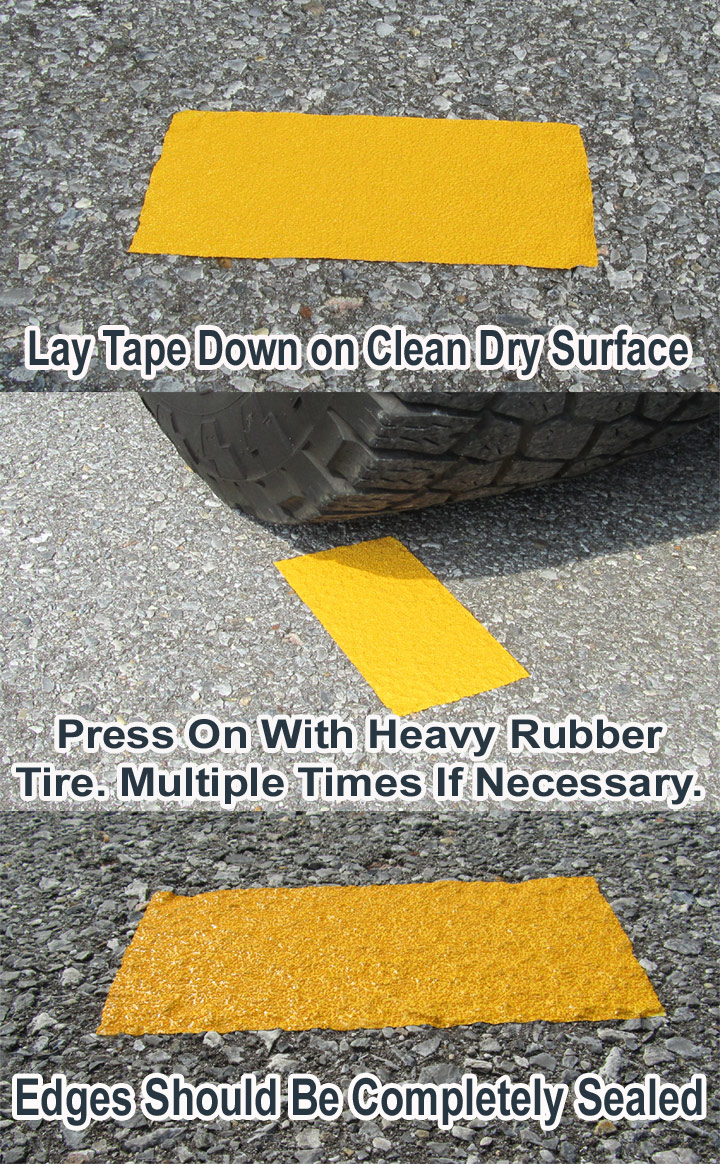

More specifically, it is an object of this invention to provide a removable, reflective, multilayer marking tape based on a thin, malleable sheet of aluminum. The top surface of the aluminum is covered with a pigmented vinyl binder. High index glass beads are embedded in the vinyl binder. A scrim of polymer felt is bonded to the bottom side of the aluminum sheet with an adhesive. The adhesive soaks into and saturates the scrim, forming a composite backing. Finally, a pressure-sensitive adhesive is applied to the bottom of the scrim.

The resultant tape solves the many problems of the prior art. The aluminum base is strong and lightweight. It provides improved tear resistance over the polymer-layered tapes of the prior art. Furthermore, the aluminum is malleable so the tape will conform to the road surface. While the polymer scrim has some memory, the entire tape has a very low system memory and thus will conform to the shape of the road and not spring back or “remember” its original configuration as was the case with the polymer-based tapes of the prior art.

Another advantage of the aluminum backing is aluminum’s superior resistance to shrinkage, weathering, and embrittlement at low temperatures. Unlike the polymers used in the prior art, aluminum is unaffected by sunlight and petrochemicals present in the roadway environment. Aluminum also has a higher durability and wear resistance.

Another advantage of the aluminum is that it is impervious to water so that water cannot soak up behind the pigmented binder causing blistering and peeling of the pigmented binder.

Another advantage of the aluminum is that it provides superior strength and less volume and weight than the polymer tapes of the prior art. Thus a given length of this tape requires less space and weighs less than those of the prior art. This facilitates shipping, storing and handling of the tape.

Yet another advantage of the aluminum base is that when the tape is gouged so that the paint and beads are removed, the gouge exposes bare aluminum which in itself is reflective. Thus the reflectivity of the tape, although diminished, is not eliminated.

The composite backing of polymer, felt scrim and adhesive reinforces the aluminum to help it resist tearing, not just while in use, but also during removal. The scrim prevents the tape from tearing during removal and thereby allows the tape to be removed in the same long strips in which it was applied. This greatly reduces the labor, time and expense spent in removing the tape, and offers a significant improvement over the metal tapes of the prior art.

While adding strength, the scrim-adhesive composite does not add significant thickness to the tape. Thus the tape does not protrude very much from the roadway, reducing stress on the tape and increasing its useful life. Furthermore, thin tape offers advantages in storing, shipping and handling. Finally, the thinness of the scrim and its lack of compressibility reduce the flexing of the tape’s surface, prolonging the life of the pigmented vinyl binder and glass beads affixed thereto.

The result of this combination is that the multilayered tape of this invention has an in-use life span of over six months, more than double that of any of the prior art tapes.

Conclusion –

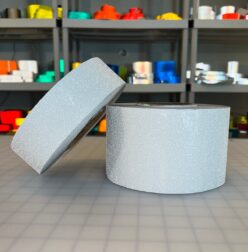

In 1988 the patent for Foil Backed Pavement Marking tape would be assigned to a company called Flex-O-Lite Incorporated. Flex-O-Lite would later be purchased by Potters Beads, the worlds largest producer of retro reflective glass beads. In 2004 the patent expired which allowed other companies to manufacture foil backed pavement tape. Aluminum based adhesive pavement tape is now manufactured by several companies. A few manufacturers are as follows – FOL Tape, Swarco Industries,

To this day, Foil backed or Aluminum based pavement tape is widely used in construction zones, parking lots, and warehouses. A 2 inch version is also used to mark basketball courts, tennis courts, pickle ball courts and other courts where delineation is needed. The same features of the original invention prove to be very applicable in all of these applications. A thin, rugged pavement marking solution never seems to go out of style.

In 1974, 3m patented pavement marking tapes. Tapes we now know as Stamark pavement marking rolls. These tapes were meant to provide quick temporary striping for roads and are still widely used in construction zones. An issue that arose with this particular product was clean removability. When peeled from a roadway, temporary pavement marking tapes often fell apart or came off in pieces. So there was no easy way to remove them when a job was done and paint or thermoplastic was ready to be applied.

In 1974, 3m patented pavement marking tapes. Tapes we now know as Stamark pavement marking rolls. These tapes were meant to provide quick temporary striping for roads and are still widely used in construction zones. An issue that arose with this particular product was clean removability. When peeled from a roadway, temporary pavement marking tapes often fell apart or came off in pieces. So there was no easy way to remove them when a job was done and paint or thermoplastic was ready to be applied. In 1982 Lukens General Industries Inc filed to patent an invention that would allow for more cleanly removable temporary pavement striping. In 1984 the patent was granted. This product would differ from 3m’s pavement tape in that its main component was aluminum sheeting or foil film. As you can see from the patent filing information below, this new tape consisted of an aluminum sheet, coated with paint and glass beads, layered with a polymer scrim, and then coated with an adhesive. So the layers are as follows from the top down – reflective glass beads, paint, aluminum, polymer scrim, and adhesive. The aluminum and polymer scrim helped the tape hold together during removal, which was one of the main goals of the invention. Also, the aluminum construction allowed the tape to mold or conform to the surface leaving very little edge, much like a coat of paint. From experience using this product, removal is as simple as peeling an edge and pulling it up. Or a torch can be used to flash the tape and cause it to release. The aluminum construction allows heat to quickly pass into the adhesive layer and vaporize it, thus releasing the tape.

In 1982 Lukens General Industries Inc filed to patent an invention that would allow for more cleanly removable temporary pavement striping. In 1984 the patent was granted. This product would differ from 3m’s pavement tape in that its main component was aluminum sheeting or foil film. As you can see from the patent filing information below, this new tape consisted of an aluminum sheet, coated with paint and glass beads, layered with a polymer scrim, and then coated with an adhesive. So the layers are as follows from the top down – reflective glass beads, paint, aluminum, polymer scrim, and adhesive. The aluminum and polymer scrim helped the tape hold together during removal, which was one of the main goals of the invention. Also, the aluminum construction allowed the tape to mold or conform to the surface leaving very little edge, much like a coat of paint. From experience using this product, removal is as simple as peeling an edge and pulling it up. Or a torch can be used to flash the tape and cause it to release. The aluminum construction allows heat to quickly pass into the adhesive layer and vaporize it, thus releasing the tape.

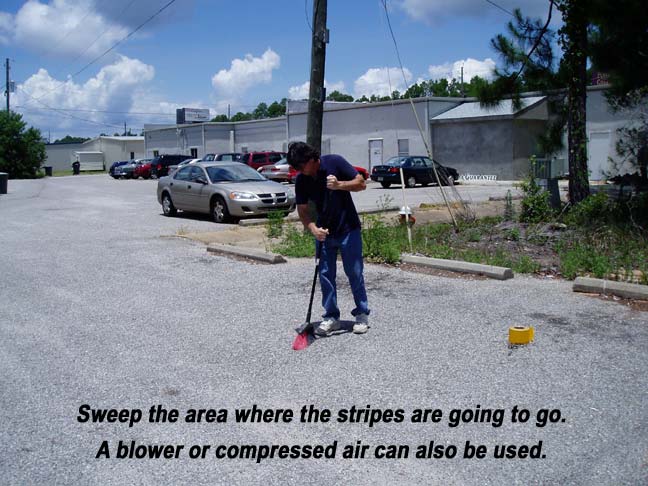

In the beginning, all stripes on roadways and parking lots were comprised of white or yellow paint that was either sprayed down, or rolled on. Today, paint is still used for permanent lines on lower traffic roads, whereas for high traffic roadways, long lasting poured on molten thermoplastic is used. When MUTCD standards required that roads be marked even when under construction, temporary methods of marking roads and highways became necessary. Paint can be used for these temporary lines, however, that requires having a paint crew on site at all times. So a durable tape to mark roads that came in rolls, was easy to install, was reflective, and removable, would be an ideal solution.

In the beginning, all stripes on roadways and parking lots were comprised of white or yellow paint that was either sprayed down, or rolled on. Today, paint is still used for permanent lines on lower traffic roads, whereas for high traffic roadways, long lasting poured on molten thermoplastic is used. When MUTCD standards required that roads be marked even when under construction, temporary methods of marking roads and highways became necessary. Paint can be used for these temporary lines, however, that requires having a paint crew on site at all times. So a durable tape to mark roads that came in rolls, was easy to install, was reflective, and removable, would be an ideal solution.